Large Capacity Rotary Drum Dryer 12T/h 20M Length For HP Vesicant

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | ISO |

| Model Number: | HG2x20 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | 12T/H 20M Length Large Capacity Rotary Drum Dryer For HP Vesicant | Application: | Industry Processing, Chemical Processing |

|---|---|---|---|

| Item: | 2x20Meter | Productive Capacity: | 12tons Per Hour |

| Driving Power: | 22kilowatt | Heating Source: | Gas |

| Revolution: | 0.6-6r/min | Install Angle: | 3-5 Degree |

| Highlight: | 20M Length Rotary Drum Dryer,Rotary Drum Dryer 12T/h,HP Vesicant Rotary Drying Machine |

||

Product Description

12T/H 20M Length Large Capacity Rotary Drum Dryer For HP Vesicant

RD type rotary dyrer is a kind of drying equipment with large handle capacity and can for continuous production.

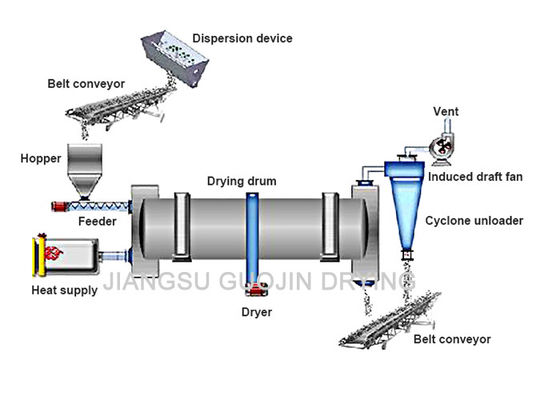

It consists of heat system, feeding device, rotary drum, driving device, discharge part and dust catcher etc.

This dryer have a big capability with wide application, and with small flow resistance, permit wide scope in operation, and easy to operate,

humidity of product can less than 1% after drying.

Product Features

- Need large quantity of material for drying.

- Level of mechnization is high, and capacity is large.

- The resistance for fluid to pass through drum is low, and energy consumption is low.

- Good adaptability to the characters of materials.

- Operation is stable, operating cost is low. Uniformity of dried product is good.

Product Working Principle

when the damp raw material is fed from one teminal, it is turned over through blades that are distributed inside the cylinder and

will be distributed uniformly in the drier and contact fully with the counter current hot air. In this way, the process of heat conduction

is increased. During the period of dry, under the effect of incine blades and hot air stream, raw material can be moved to drier and

discharged from discharged form discharging valve.

Product Application

Powder & particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc.

Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc.

Corrosive material: Distillers ‘grains, Fertilizer, animal dung, slag etc.

Biomass material: Sawdust, wood chips etc.

Technical Parameters

| Item | Productive capacity(t/h) | Revolution(r/min) | Motor power(kw) | Install angle(o) | Temp. of final |

| Ø1.0x5.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | <1.5% |

| Ø1.2x6-10 | 1.5-3 | 0.6-6 | 5.5 | 3-5 | <1.5% |

| Ø1.5x12-18 | 3-5.5 | 0.6-6 | 15 | 3-5 | <1.5% |

| Ø1.8x12-18 | 5-6.5 | 0.6-6 | 18.5 | 3-5 | <1.5% |

| Ø2.2x12-22 | 7-12 | 0.6-6 | 22 | 3-5 | <1.5% |

| Ø2.4x15-20 | 9-15 | 0.6-6 | 30 | 3-5 | <1.5% |

| Ø3.0x25 | 16 | 0.6-6 | 55 | 3-5 | <1.5% |

Product Flowchart

![]()

Production Show

![]()

electrical, steam, natural gas or other

| 1.International standard with ISO, CE certificate. |

|

2.Simple system, safe and easy operation. |

|

3.Flexibility in fuels used (NG, Oil, Coal ect.). |

|

4.Year of experience with all types of dryers. |

|

5.Capable of installation anywhere in world. |

|

6.In house engineering for custom fit applications. |

|

7.Proven design. |