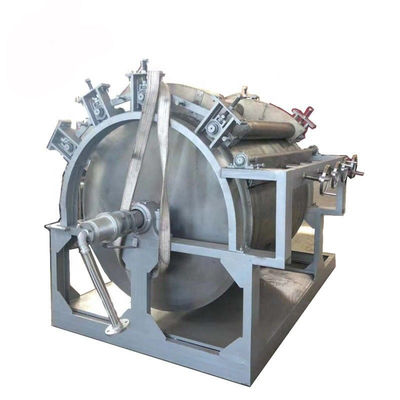

Industrial Double Roller Scraper Rotary Drum Dryer

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM |

| Certification: | CE;ISO |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Type: | Rotary Drum Dryer | Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing |

|---|---|---|---|

| Condition: | New | Voltage: | 380V/50HZ 415V/50HZ/60Hz |

| Power(W): | 2.2-18.5KW | Dimension(L*W*H): | Diameter 600-3500mm |

| Warranty: | 1 Year | Name: | Roller Scraper Dryer |

| Size Of Cylinder: | Diameter600-1800*length1000-4100mm | Effective Heating Area: | 1.12-10.60 |

| Drying Capacity: | 40-630kg | Steam Consumption: | 100-1575kg/h |

| Conductive Oil: | Can Reach 300℃ | Power Of Motor: | 2.2kw-18.5kw |

| Material: | SS304/SS316L | Heating Source: | Steam, Electrcity, Conductive Oil |

| Model Size: | Customized According To Needs | After-sales Service Provided: | Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service |

| Weight: | 0.85-6.15Tons | ||

| Highlight: | Double Roller Scraper Rotary Drum Dryer,Industrial Rotary Drum Dryer,1575kg/h Rotary Drum Dryer |

||

Product Description

Product Application

Double Roller scraper dryer is through the rotation of the cylinder, in a heat conduction way to dry the liquid phase material or ribbon material which is attached to the outer wall of the drum dryer, it is a continuous operation equipment. The material to be dried is fed from the upper tank into the feeding tank of the double drum scraper dryer. The drying drum is driven at the specified speed by the drive. Material from the districuting coating device, to form a coating on the drum wall. The cylinder continuously into the heating medium, heating the cylinder, the heat transfer from the cylinder wall to make the water content vaporized, and then the dried qualified material wil be scraped by the scraper, sent by the screw conveyor to the tank, then packaging. The removed moisture from the evaporation, depending on its nature through the closed cover, into the corresponding treatment device; generally it is water vapor, can be directly from the top of the exhaust pipe into the atmosphere.

Product Description

|

SPECIFICATIONS FOR TG ROLLER DRUM DRYER

|

||||||

|

Model

|

Sizes of cylinder diameter*Length

|

Effective heating area(m2)

|

(Kg.H2O/m2.h)

Drying capacity

|

Steam consumption(kg/h)

|

Size L*W*H(mm)

Power of motor

|

Weight(kg)

|

|

TG-600

|

600*800

|

1.12

|

40-70

|

100-175

|

1700*800*1500

2.2kw

|

850

|

|

TG-700

|

700*1000

|

1.65

|

60-90

|

150-225

|

2100*1000*1800

3kw

|

1210

|

|

TG-800

|

800*1200

|

2.26

|

90-130

|

225-325

|

2500*1100*1980

4Kw

|

1700

|

|

TG-1000

|

1000*1400

|

3.30

|

130-190

|

325-475

|

2700*1300*2250

5.5kw

|

2100

|

|

TG-1200

|

1200*1500

|

4.24

|

160-250

|

400-625

|

2800*1500*2450

7.5kw

|

2650

|

|

TG-1400

|

1400*1600

|

5.28

|

210-310

|

525-775

|

3150*1700*2800

11kw

|

3220

|

|

TG-1600

|

1600*1800

|

6.79

|

270-400

|

675-1000

|

3350*1900*3150

11Kw

|

4350

|

|

TG-1800

|

1800*2000

|

8.48

|

330-500

|

825-1250

|

3600*2050*3500

|

5100

|

|

TG-1800A

|

1800*2500

|

10.60

|

420-630

|

1050-1575

|

4100*2050*3500

|

6150

|

Main Features

1. High thermal efficiency: the supply heat to the cylinder, in addition to a small amount of heat radiation and a few heat loss at the end part of the cylinder, the majority of heat for evaporation, thermal efficiency can be as high as 80-90%.

2. The drying rate is high: the wet coating of the wal on the heat transfer and mass transfer process, from inside to outside, the same direction, the temperature gradient is large, so that the coating surface maintains a high evaporation intensity, generally up to 20-70kg. H2O/m2.h.3. The dry quality of the product is stability: drum heating mode is facilitate to control, the cylinder temperature and the wall of the heat transfer rate can be relatively stable, so that the coating can be in a stable heat transfer state of drying, the quality of the product can be guaranteed.

Machine Parts

Name: Scaper

Brand: Haomai

Original: Jiangsu, China

High-quality scraper with balanced surface contact and long service life.

Name: Heat System

Brand: Haomai

Original: Jiangsu, China

Heat system could be steam, Conduct oil, it is very save energy. The picture is conduct oil heat system.

Name: Top Cover

Brand: Haomai

Original: Jiangmin, China

Let the water vapor discharge quickly, and the tail gas treatment can be carried out, and the discharge of tail gas meets the environmental requirements.

Name: Pneumatic pump

Brand: Haomai

Original: Jiangsu, China

The pneumatic pump precisely adjusts the distance between the scraper and the surface of the drum.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.![]()