6.5t/H Coal Slime Rotary Drying Equipment With 18.5KW Motor

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | ISO |

| Model Number: | RD-1.8*12-18 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | Peat Coal Slime Rotary Drying Equipment | Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing,Pharmaceutical Processing |

|---|---|---|---|

| Model Type: | RD-1.8*12-18 | Item: | 1.8*12-18 M |

| Productive Capacity: | 5-6.5 T/h | Revolution: | 0.6-6 R/min |

| Motor Power: | 18.5 Kw | Install Angle: | 3-5 |

| Final Temperature: | <1.5% | Heating Source: | Steam, Natural Gas,Thermal Oil |

| Highlight: | Coal Slime Rotary Drying Equipment,6.5t/h Rotary Drying Equipment,Coal Slime Rotary Drying Machine |

||

Product Description

Peat Coal Slime Rotary Drying Equipment

The coal slime is coal washing process of industrial waste residue. Due to coal slurry with high moisture content, high viscosity, high water, and low calorific value such many other adverse conditions, it is difficult to realize industrial use, based on the coal slime industry market and the characteristics of coal slurry, through many times technical research and practice,Guojin Factory developed a new generation of coal slime drying system meticulously, drying product moisture is less than 15%, the calorific value of coal can achieve 2800-4200 kcal/kg,it is a good fuel of coal boiler. This set of equipment technology is mature, stable running, convenient operation and maintenance.

Product Features

1. Guojin coal slime dryer, with strong overload capacity, large quantity, less fuel consumption, dry low cost;

2. Adopts downstream drying method, the flue gas, and wet material into the drying machine by one side of the dryer, it can take advantage of the high-temperature flue gas to obtain high evaporation strength, the low outlet temperature of the dryer, with high thermal efficiency.

3. It can change operation parameters according to the different material properties, the material in the dryer cylinder body can form stable whole curtain fabric, and the heat exchange more adequately;

4. New type feeding and discharging device, preventing drum dryer feeding jams, discontinuous and uneven return phenomenon, reduce the load of dust removal system;

5. New type of internal structure, to strengthen the effect on scattered material cleaning and heat conduction, eliminates the cylinder to moisture, has a more flexible adaption of sticky and moisture of the materials;

6. New type coal slime drying equipment to achieve the "zero thrust", greatly reducing the wheel wear, the cylinder has a smooth and reliable operation;

7. The drying machine adopts "self-aligning roller device", make the wheel and roll ring with a linear contact, thus greatly reduces the wear and power loss;

8. Adopt unique large coal slime delay drying technology, guarantee the coal slime drying uniformity.

Product Application

(1) Ore:ore, slag, mineral power, limestone, quartz, fluorite powder, iron ore, metal ore concentrates, metal tailings,etc.

(2) Metal: metal powder, iron powder, iron filings, steel scrap, copper filings, etc.

(3) Chemical industry: gypsum powder of desulphurization gypsum stir-frying half water model and building gypsum powder,clay,diatomaceous earth, kaolin,bauxite

(4) Coal: raw coal,coal slime, coal,coal ash,coal cinder

(5) Sand: sand,quartz sand,moulding sand,river sand

(6) Various crystals: light calcium carbonate, activated clay, magnetic powder, graphite, mineral mud, clay, lime slurry, ore slurry, phosphorus slag, aluminum red mud, feldspar powder, fly ash, blue carbon, potassium, sodium, calcium, barium and alkali metal or silicate minerals in the alkali metal.

(7) Wood: sawdust, small wood chips, wood veneer.

(8) Fertilizer: compound fertilizer, organic fertilizers, inorganic fertilizers, ammonium sulfate fertilizer

(9) Agriculture: straw, grass, turf.

(10) Animal manure: chicken manure, duck manure, cow dung, etc.

Technical Parameters

| Item | Productive capacity(t/h) | Revolution(r/min) | Motor power(kw) | Install angle(o) | Temp. of final |

| Ø1.0x5.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | <1.5% |

| Ø1.2x6-10 | 1.5-3 | 0.6-6 | 5.5 | 3-5 | <1.5% |

| Ø1.5x12-18 | 3-5.5 | 0.6-6 | 15 | 3-5 | <1.5% |

| Ø1.8x12-18 | 5-6.5 | 0.6-6 | 18.5 | 3-5 | <1.5% |

| Ø2.2x12-22 | 7-12 | 0.6-6 | 22 | 3-5 | <1.5% |

| Ø2.4x15-20 | 9-15 | 0.6-6 | 30 | 3-5 | <1.5% |

| Ø3.0x25 | 16 | 0.6-6 | 55 | 3-5 | <1.5% |

![]()

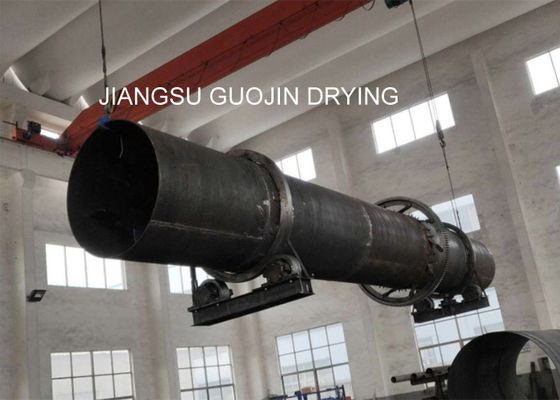

Production Show

![]()

electrical, steam, natural gas or other