200L Three Dimensional Mixer 12r/min For Food Powder

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | ISO |

| Model Number: | THDM-200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | Three Dimensional Movement Mixer For Food Powder | Application: | Medicine Processing, Chemicals Processing, Food Processing |

|---|---|---|---|

| Model Type: | THDM-200 | Barrel Volume: | 200L |

| Max Loading Volume: | 170L | Max Loading Weight: | 150kg |

| Spindle Rotation Speed: | 12r/min | Motor Power: | 3kw |

| Weight: | 750kg | Overall Dimension: | 1300x1600x1500mm |

| Highlight: | 200L Three Dimensional Mixer,Three Dimensional Mixer 12r/min,200l 3d mixer |

||

Product Description

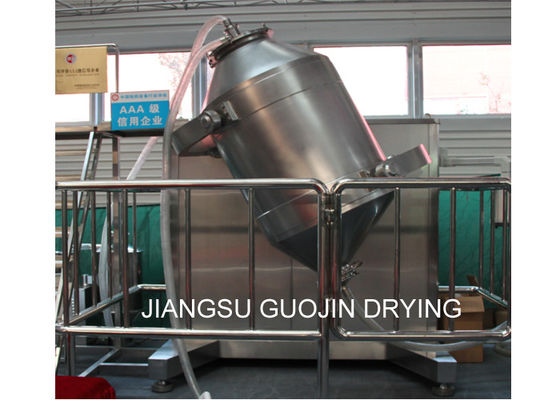

Three Dimensional Movement Mixer For Food Powder

Three dimension mixer. The mixing barrel of the machine moves in multi-direction. For the materials, there is no centrifugal function, without the specification gravity segregation and the layer division. For each of build-up phenomenon, there is the remarkable weight rate. The mixing rate is high. The machine is the desired one of various mixers at present.

Technical Parameters

| Type | THDM-5 | THDM-100 | THDM-200 | THDM-400 | THDM-600 | THDM-800 | THDM-1000 |

| Material barrel volume(L) | 5 | 100 | 200 | 400 | 600 | 800 | 1000 |

| Max loading volume(L) | 4.25 | 85 | 170 | 340 | 510 | 680 | 850 |

| Max loading weight(kg) | 5 | 80 | 150 | 200 | 300 | 400 | 500 |

| Spindle rotation speed(r/min) | 24 | 15 | 12 | 10 | 10 | 10 | 10 |

| Motor power(kw) | 0.37 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 |

| Overall dimensions(mm) | 600*1000*1000 | 1200*1800*1500 | 1300*1600*1500 | 1500*2200*1500 | 1850*2500*1650 | 1900*2400*2100 | 1950*2500*2400 |

| Weight(kg) | 150 | 500 | 750 | 1200 | 1500 | 1650 | 1800 |

Product Working Principle

During the period of operation, because the mixing drum has multi-directional actions of motion, it speeds up the fluid and diffused effect of raw material. Meanwhile it avoids the phenomenon of segregation and accumulation caused by centrifugal effect in ordinary mixer and no dear corner. It can guarantee the best quality of mixed raw material.

Structure: this machine consists of stand, transmission system, electric control system, multi-directional motion mechanism, mixing drum and so on. The mixing drum contacted with raw material is made of stainless steel. The inner and outer wall of drum is polished.

![]()

Production Show

electrical, steam, natural gas or other