24KW Pipeline Dryer 250kg/h For Heat Sensitive Materials

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | CE |

| Model Number: | PCD250 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | Powder Cyclone Airflow Flash Pipeline Type Drier | Model Type: | PCD250 |

|---|---|---|---|

| Water Evaporation: | 250kg/h | Equipped Power: | 24KW |

| Occupied Area: | 51M2 | Height: | 13M |

| Heating Source: | Steam,Natural Gas, LPG, Coal, Electricity | ||

| Highlight: | 24KW Pipeline Dryer,Pipeline Dryer 250kg/h,24KW Airflow Dryer |

||

Product Description

Powder Cyclone Airflow Flash Pipeline Type Drier

The air flow dryer uses high-speed flow of hot air to make the wet starch suspended in it. It has the characteristics of high heat transfer coefficient, large heat transfer area and short drying time. Airflow drying, also called instantaneous drying, is the application of dilute phase transportation in solid fluidization. This method makes the heating medium and the dry solid particles in direct contact and suspends in the fluid so that the two-phase contact area is large and the heat and mass transfer process is strengthened.

It is widely used in the drying unit operation of the bulk material. Especially suitable for wet materials with high moisture content and paste, as well as materials that cannot be dried by other air drying methods. Such as vinyl acetate, calcined gypsum, Electrolytic manganese dioxide, fluorite, silica catalyst, bone powder, synthetic resin, active gluten, activated clay, chemical filter cake, copper sulfate, calcium phosphate, phosphate starch, dyes, slime, clay cement, aluminium hydroxide Barium hydroxide, lime, biological products, carbon black, sludge residue, iron oxide, organic fuel, corn protein feed, wet mud, mica powder, Chemicals, pigments, etc.

PCD Pneumatic Conveying Dryer Features

1. Powerful drying. Little invest and the amount of evaporated moisture is high ( from 50kgH2O/h to 2000kgH2O/h)

2. The drying time is short. The series is suitable in strong heat sensitive materials. The finished product is seperated from outside, and no pollution with high quality.

3. The equipment is a total set, the heat source can be shoose from steam, coal fuel, oil fuel and gas fuel hot air furnace.

PCD Pneumatic Conveying Dryer Application

This dryer is suitable for high moisture materials, paste materials, and other raw materials that can’t be dried with other airflow dryers; such as copolymer of vinyl acetate and chloroethylene, cellulose acetate, catalyst, C.M.C, CT-1 resin, burnt plaster, electrolytic manganese dioxide, anthraquinone ammonium sulphonate, flour, diatomaceous, silica gel catalyst, born powder, potassium perchlorate sulfonamide, synthesis resin, active gluten, active argil, chemical filter cake, titanium dioxide, decanedioic acid, cooper sulphate, aluminum sulphate, sodium sulphate, calcium phosphate, starch, dyestuff, calcium citrate, coal earth, cement, compounds, ferric oxide, organic fuel, maize albumen feed, mica powder, medicine, dyestuff, paper pulp of potassium perchromate, lees residue, and etc.

PCD Pneumatic Conveying Dryer Technical Parameters

|

Type |

Moisture(kg/h) |

Equipped power(kw) |

Occupied area(m2) |

Height(m) |

|

PCD50 |

50 |

7 |

16 |

9 |

|

PCD100 |

100 |

13 |

26 |

11 |

|

PCD200 |

200 |

21 |

35 |

11 |

|

PCD250 |

250 |

24 |

51 |

13 |

|

PCD500 |

500 |

43 |

78 |

13 |

|

PCD1000 |

1000 |

100 |

105 |

15 |

|

PCD1500 |

1500 |

150 |

200 |

16 |

PCD Pneumatic Conveying Dryer Working Principle

The PCD Series Airflow Dryer can rapidly remove moisture from the granules or powder that is easy to dehydrate (mainly water in surface). Because of the raw material stayed in the dryer only for a short time so the quality of finished products can be controlled to the best conditions. Our factory developed a reinforced device with stepless speed exchange based on basic dryer. When the wet raw material is fed through screw feeder, it will be fully mixed with hot airflow and the rotating knives will crush it into fine granule. The granule dries during the movement to the outlet and it finally enters the drying pipe under absorbing of air force. The humidity and heavy granule that is not absorbing of air force. At the place it is dried further. The humidity and heavy granule that is not absorbed by air will be continuously crushed and dried until it entering the drying pipe.

PCD Pneumatic Conveying Dryer Sketch of Structure

![]()

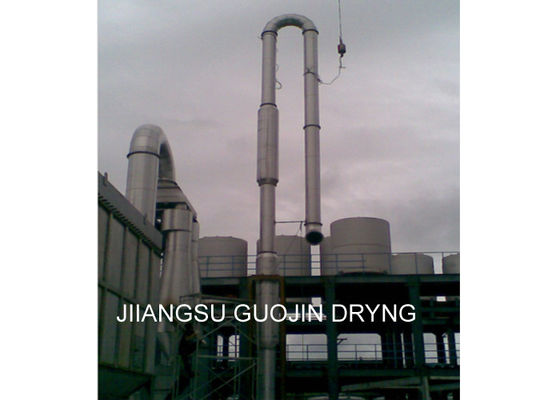

PCD Pneumatic Conveying Dryer Show