Slag Muck Offscum Airflow Dryer 13KW With High Heat Transfer Coefficient

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | CE |

| Model Number: | PCD100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | Airflow Type Airflow Dryer For Offscum / Discard / Feigh / Slag Muck | Model Type: | PCD100 |

|---|---|---|---|

| Water Evaporation: | 100kg/h | Equipped Power: | 13KW |

| Occupied Area: | 26M2 | Height: | 11M |

| Heating Source: | Steam,Natural Gas, LPG, Coal, Electricity | ||

| Highlight: | Offscum Airflow Dryer,Slag Muck Airflow Dryer,Air Flow Dryer 13KW |

||

Product Description

Airflow Type Airflow Dryer for offscum / discard / feigh / slag muck

Pneumatic and Airflow dryer drying machine is used to suspend the wet material in the process of air flow through the hot air flow. High heat transfer coefficient, large heat transfer area and short drying time. Airflow dryer drying is also known as "instantaneous drying", which is the application of solid fluidization in drying.

The method is to make direct contact with the heating medium and solid particles being dry, and make the stay dry solid particles suspended in a fluid, and two large contact areas, to strengthen the heat and mass transfer process, is widely used for material drying unit operation.

PCD Pneumatic Conveying Dryer Features

1. Powerful drying. Little invest and the amount of evaporated moisture is high ( from 50kgH2O/h to 2000kgH2O/h)

2. The drying time is short. The series is suitable in strong heat sensitive materials. The finished product is seperated from outside, and no pollution with high quality.

3. The equipment is a total set, the heat source can be shoose from steam, coal fuel, oil fuel and gas fuel hot air furnace.

PCD Pneumatic Conveying Dryer Application

Ceramic industry: Kaolin, bentonite, clay, etc.

Foodstuff industry: Soybean protein, gelatinized starch, vinasse, triticum, wheat starch, etc.

Organics: Atrazine, lauric acid cadmium, benzoic acid, sodium oxalate, acetyl cellulose, etc.

Dyestuff: Anthraquinones, black iron oxide, indigo dye, butyrate, titanium oxide, zinc sulfide, various azo dye intermediates, etc.

Inorganic: Borax, calcium carbonate, hydrogen peroxide, etc.

Substance: Copper suifate, ferrix oxide, three antimony oxide, all kinds of metal salt, synthetic cryolite, etc

PCD Pneumatic Conveying Dryer Technical Parameters

|

Type |

Moisture(kg/h) |

Equipped power(kw) |

Occupied area(m2) |

Height(m) |

|

PCD50 |

50 |

7 |

16 |

9 |

|

PCD100 |

100 |

13 |

26 |

11 |

|

PCD200 |

200 |

21 |

35 |

11 |

|

PCD250 |

250 |

24 |

51 |

13 |

|

PCD500 |

500 |

43 |

78 |

13 |

|

PCD1000 |

1000 |

100 |

105 |

15 |

|

PCD1500 |

1500 |

150 |

200 |

16 |

PCD Pneumatic Conveying Dryer Maintainance

Daily maintenance contents:

(1). Check the automatic drain valve on the front filter before each shift.

(2). Check whether the change of tower and lift is normal.

(3). Check operating conditions, inlet pressure, inlet temperature and air flow.

(4). Check for moisture indicators, blue for dry and pink for moisture.

(5). Check whether the muffler is dirty, and the regeneration tower back pressure is too high to indicate that the muffler needs to be replaced.

(6). Check the pressure drop of the front filter and the back filter, if the pressure drops more than 0.5 bar, change the filter element.

Monthly maintenance contents:

(1). Check the control gas of the unheated and airflow dryer.Replace when necessary.

(2). Check the filter element of air flow dryer guide filter, if necessary, please replace it.

(3). Check the suction filter of air flow dryer, if necessary, please replace it.

Maintain content quarterly:

Check the front and rear filters, check for blockages and possible damage, and replace them as needed. Purge the relief valve with compressed air. Check the dew-point status of the output.

PCD Pneumatic Conveying Dryer Sketch of Structure

![]()

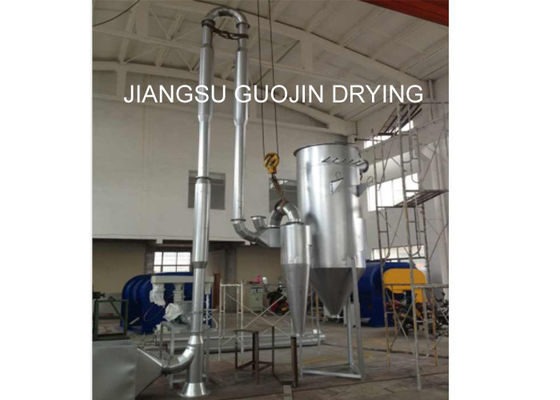

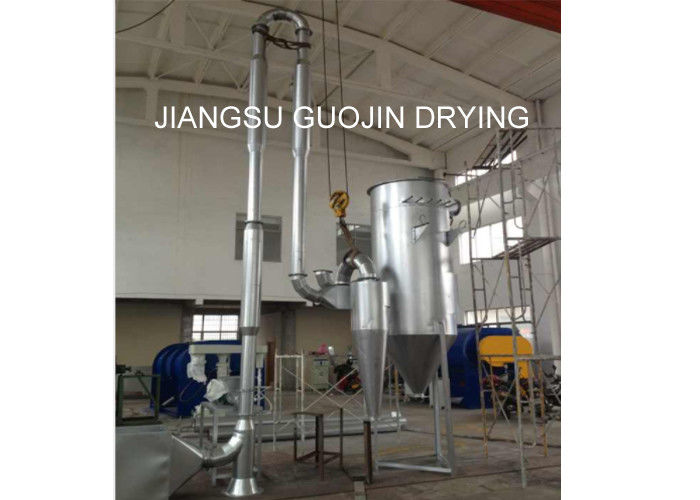

PCD Pneumatic Conveying Dryer Show