Double Cone Shaped Vacuum Rotary Dryer With 1000L Tank

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | ISO |

| Model Number: | DCRD-1000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | Easy To Clean Double Cone-Shaped Vacuum Rotary Dryer | Application: | Food Processing |

|---|---|---|---|

| Model Type: | DCRD-1000 | Volume Inside Of Tank: | 1000 L |

| Max Loading Capacity: | 400 L | Max Loading Weight: | 200 Kg |

| Revolution: | 3-13 Rpm | Heating Area: | 5.1 M2 |

| Motor Power: | 3 Kw | Rotaing Height: | 2800 Mm |

| Weight: | 2800 Kg | Design Pressure Inside Of Tank: | -0.1~0.15Mpa |

| Design Pressure Of Jacket: | <0.3 | ||

| Highlight: | Double Cone Vacuum Rotary Dryer,1000L Tank Vacuum Rotary Dryer,1000l tank double cone vacuum dryer |

||

Product Description

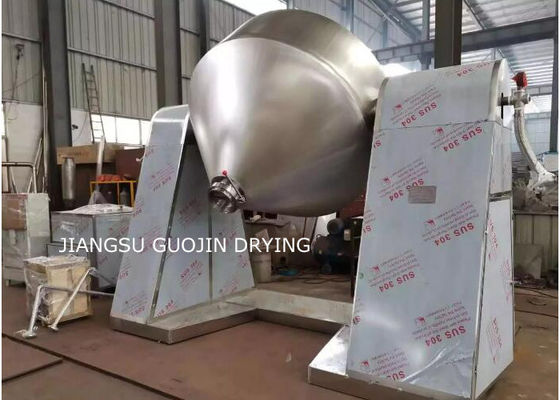

Easy To Clean Double Cone-Shaped Vacuum Rotary Dryer

DCRD double cone vacuum dryer is a new type of drying equipment which combines similar product technologies at both home and abroad. This rotary vacuum dryer possesses a belt and chain two-stage elastic connection modes. With a low center of gravity, this drying machine can operate smoothly. Heating medium and vacuum system adopt reliable mechanical seal or rotating joint, so as to avoid defects such as the regular packing seal are easy to leak. On this basis, we modify this double cone vacuum dryer. It not only embodies the humanized design concept but also meets the GMP standards.

Biconical rotating vacuum dryer is the dryer suitable for ultra vacuum drying of all kinds of humid, crystalline and amorphous products.

Fully heated and insulated drum, rotating at low speed under high vacuum, continuously renovating the product in contact with the heated walls.

Working Principle

In order to achieve rapid drying at low temperatures, including the drying of deep pores, in a way that does not damage the product, specialized drying technology – vacuum drying – must be used.

The complete product will move into the chamber. The pressure reduces for so long the saturated steam tension is reached. The water will discharge through the vacuum chamber from that point. The raw material is charged in batches & is subjected to indirect heating while at the same time undergoing rotary motion of the cone assembly. The double conical shape of the dryer ensures efficient circulation of hot liquid heating media. Drying takes place when heat flows from the outer cone through a jacket, and vacuum is applied in the inner cone. The drying operation is based on the principle that water or other volatile product moves from a zone of low pressure. This is accomplished by warming the product to be dried to raise the vapor pressure of the absorbed or free liquid by vacuum or by sweeping it with Air or Nitrogen current. Thus the essential conditions for effective drying are achieved by uniform heat transfer throughout the batch and rapid removal of the vapor. The vacuum is applied gradually with PLC control by throttling.

Most times the specific heat from the evaporating product is lower than from the base material. This material ensures that the temperature will drop slowly or even not. The pressure (vacuum) will achieve any part of the product so the moisture will evaporate. For a short period there results in a homogeneous temperature.

Product Application

DCRD double cone rotary vacuum dryer is applicable for drying and mixing powdery and granular materials in the pharmaceutical, food, chemical, dye and other industries. It is especially suitable for the following materials:

1. Thermosensitive materials that cannot withstand high temperature

2. Easily oxidized and dangerous materials

3. Materials whose solvent should be recovered and materials of poisonous gas

4. Materials required low residual volatile content

5. Materials with requirements on crystal shape

Product Features

1) Use automatic constant temperature control if the heat source is thermal oil. It can be used for drying biology products and mineral raw materials. The temperature of operation can be adjusted form 20 ~ 160°C.

2) The heat efficiency will be 2 times or higher comparing to the common dryer.

3) The heating method is indirect drying so the raw material will not be polluted. It is in conformity with the requirement of GMP. 4) The dryer is easy for cleaning and maintenance.

Technical Parameters

| Model | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| Volume inside of tank(L) | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| Max loading capacity(L) | 40 | 140 | 200 | 300 | 400 | 600 | 800 | 1400 | 1800 | 2000 |

| Max loading weight(kg) | 20 | 70 | 100 | 150 | 200 | 300 | 400 | 700 | 900 | 1000 |

| Revolution(rpm) | 3-13 | 6 | 5 | 4 | 4 | 4 | ||||

| Heating area(M2) | 1.1 | 2.3 | 2.8 | 3.9 | 5.1 | 6.5 | 8.2 | 12.2 | 16.5 | 18.2 |

| Motor power(kw) | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Occupied area(mm) | 2160*800 | 2160*800 | 2350*800 | 2560*1000 | 2860*1300 | 3060*1300 | 3260*1400 | 3760*1800 | 3960*2000 | 4400*2500 |

| Rotating height(mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

| Design pressure of tank(Mpa) | -0.1~0.15 | |||||||||

| Desing pressure of jacket(Mpa) | <0.3 | |||||||||

| Weight(kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |

Schmatic of Installation

![]()

Product Show

electrical, steam, natural gas or other