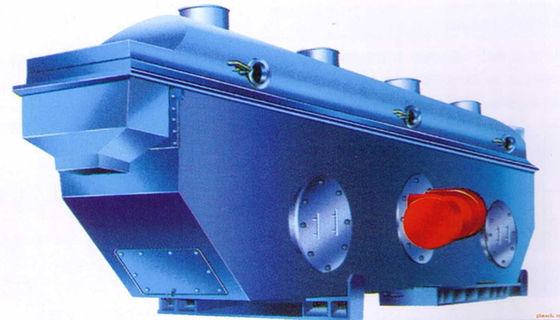

Vibrating Rectilinear Vacuum Fluid Bed Dryer Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM |

| Certification: | CE;ISO |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Type: | Rectilinear Vibrating-Fluidizing Dryer | Model Number: | ZLG 6*0.45 |

|---|---|---|---|

| Power: | 2.2 Kw | Voltage: | 380 V |

| Weight & Size: | According To The Specific Design | Material: | Stainless Steel, Iron Steel Or A3 |

| Area Of Fluidized-bed: | 2.7 M2 | Temperature Of Inlet Air: | 70-140 ℃ |

| Temperature Of Outlet: | 40-70 ℃ | Capacity To Vapor Moisture: | 80-100 Kg / H |

| Highlight: | Vacuum Fluid Bed Dryer Machine,Rectilinear Fluid Bed Dryer Machine,Vacuum Fluidized Bed Spray Granulation |

||

Product Description

Vibrating Rectilinear Vacuum Fluid Bed Dryer Machine

Technical Parameters:

| Item Name | ZLG 6*0.45 Series Rectilinear Vibrating-Fluidizing Dryer |

| Area of Fluidized-bed | 2.7 m2 |

| Temperature of Inlet Air | 70-140 ℃ |

| Temperature of Outlet | 40-70 ℃ |

| Capacity to Vapor Moisture | 80-100 kg / h |

| Motore Model | YZS 15-6 |

| Motore Power | 1.1*2 |

Features:

1. The vibration created by motor is stable in operation and convenient in maintenance, low noise and long life.

2. High thermal efficiency, raw material is heats evenly and heated evenly and heat exchange is fully used and dry capacity is high. Compared with ordinary drier, the energy can be saved about 30%.

3. It is good in regulation and wide in suitability. The thickness of raw material layer and movable speed inside the maching and the amolitude can be adjusted through continuous variable speed.

4. It is small for damaging the surface of raw material. The equipment can be used for drying raw materials that are easy broken. The drying effect can not affected even if raw materials have irregular shape.

5. A fully enclosed structure, effectively the material and the air space between the cross infection of the working environment clean.

6. You can string multi-set to raise capacity of raw materials, if the raw material contain high moisture such as polyacrylamide.

Principle:

Raw material is fed into the machine and moves forward continuously along with the level of fluidized-bed under the action of vibration. The hot air passes through fluidized-bed and carries out heat exchange with damp raw material. Then the damp air is exhausted out through cyclone separator and the dry raw material is discharged through discharge outlet.

![]()

Contact me

![]()