Dense Phase Pneumatic Conveyor For Cement Powder Dry Fly Ash

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | ISO |

| Model Number: | DPCS-1.0 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets per month |

|

Detail Information |

|||

| Product Name: | Cement Powder Dry Fly Ash Dense Phase Pneumatic Conveyor | Model: | DPCS-1.0 |

|---|---|---|---|

| Body Inner Diameter Volume: | 1000MM | Total Volume: | 1.0M3 |

| Body Material: | Q235-B | Operation Temperature: | <120 Degree |

| Diameter Of Feeder Pipe: | 200mm | Max. Design Pressure: | 0.78 Mpa |

| Operation Pressure: | 0.2-0.5Mpa(Basis On The Conveying Distance) | Max. Conveying Distance: | <1000meter |

| Outlet Conveying Diameter: | DN100 | Air Consumption: | 5-10M3/min |

| Highlight: | Cement Powder Dense Phase Pneumatic Conveyor,Q235B Dense Phase Pneumatic Conveyor,Dry Fly Ash Pneumatic Conveying System |

||

Product Description

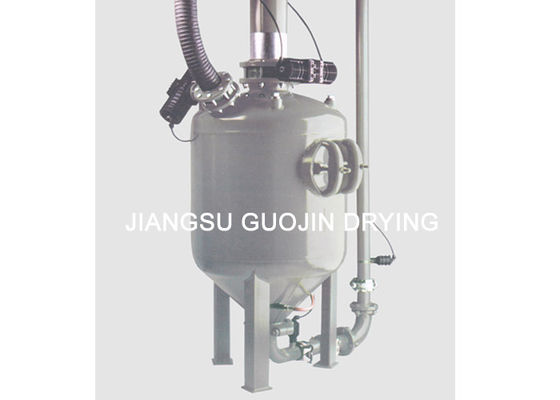

Cement powder Dry Fly Ash Dense Phase Pneumatic Conveyor

Dense phase transport, also known as airflow transport, utilizes the energy of the airflow to transport particulate material along the airflow direction in a closed duct. It is a specific application of fluidization technology. The pneumatic conveying device is simple in structure, easy to operate, and can be used for horizontal, Vertical or oblique transport, physical or chemical operations such as heating, cooling, drying and gas grading of materials can be carried out simultaneously during transport. Materials which has a lot of water content, and it has adhesiveness or materials which are easy to generate static electricity during high-speed movement are not suitable for pneumatic conveying.

Product Application

1. It can transport almost all powder and particle materials.

2. It can be transported long distance.

3. It can be sent from one point to many points.

4. Can start in full tube state

Product Features

1. Pneumatic conveying system are relatively economical to install and operate

2. Pneumatic conveying system are totally enclosed and if required can operate entirely without moving parts coming into contact with the conveyed material. Being enclosed there are hygiene & cleanlinesss benefits

3. A pneumatic conveying system can convey a product to any place with tubes. its flexible.

4. Pneumatic conveying system offer greatly reduced capital cost for long distance conveying.

5. PLC full automation

6. Pneumatic Conveying System are much better suitable to powder handling than mechanical conveyor because the conveyance channels used in pneumatic conveyors are completely enclosed.

7.Pneumatic conveyors can be designed to move products between floor levels and around difficult angles.

8. The whole system is composed of compressed air source, pneumatic vessel, control cabinet,conveying pipe and ash storage.

Product Paremeter

| Model | DPCS-1.0 |

| Body Inner diameter(mm) | 1000 |

| Total volume(M3) | 1.0 |

| Body material | Q235-B |

| Operation Temperature(oC) | <120 |

| Max. design pressure(Mpa) | 0.78 |

| Operation pressure(Mpa) | 0.2-0.5(Basis on the conveying distance) |

| Max. conveying distance(m) | <1000 |

| Outlet conveying diameter | DN100 |

| Air consumption(m3/min) | 5-10 |

Product Picture

![]()

Contact me

![]()