150mm Diameter Disc SS304 SS316 Calcium Stearate Spray Dryer

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | ISO |

| Model Number: | RWSD-150 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Nude packing |

| Delivery Time: | 30-40days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Model Type: | RWSD-150 | Place Of Origin: | Jiangsu, China |

|---|---|---|---|

| Voltage: | 380V Or 240V Or 415V | Application: | Chemicals Industry, Plastics Industry, Food Industry,Pharmaceutical Industry |

| Water Evaporation: | 150kg/h | Spray Disc Diameter: | 150mm |

| Machine Material: | SS 304 / 316 | Inlet Air Temperature: | ~140~350 |

| Outlet Air Temperature: | ~80~90 | Heating Source: | Steam & Electricity & Gas Oil |

| Highlight: | Calcium Stearate Spray Dryer,150mm Diameter Disc Spray Dryer,SS316 Spray Drying Machine |

||

Product Description

Stainless Steel Phama Calcium Stearate Spray Dryers

The spray machine for drying is the technology most widely used in the liquid technology shaping and in the drying industry. The drying technology is the most suitable for producing solid powder or particle products from liquid materials, such as: solvent, emulsion, suspension and pumpable paste states, fro this reason, when the particle size and distribution of the final products, residual water contents. Mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technology.

Product Features

1. After the spraying of the liquid material, the speed of drying is fast, the surface area of the material will be increase greatly. In the hot-air flow, 95%-98% of water can be evaporated at a moment. The time of completing the drying needs only several seconds.

2.This is especially suitable for drying the heat sensitive materials. Its final products own the good uniformity, mobility, dissolving capacity. And the final products are high in their purity and good in quality.

3. The production procedures are simple and the operation and control are easy. The liquid with the moisture contents 40-60%(for special materials, the contents may reach 90%), can dried into the powder or particle products once a time.

4. After the drying, there is no need for smashing and sorting, so as to reduce the operation procedures in the production and to enhance the product purity. The product particle diameters, looseness and water contents can be adjusted through changing the operation in a certain scope. It is convenient to carry out the control and management.

Technical Parameter

| Model | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| Inlet temperature | 140-350 automatic control | |||||

| Outlet temperature | ~80-90 | |||||

| Max. moisture evaporation | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| Centrifugal spray hear drive | Compressed air drive | Machanical drive | ||||

| Speed | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| Spray disc diameter | 50 | 100 | 120 | 140 | 150 | 180-340 |

| Heat source | electric | electricity+steam | Electricity+steam,fuel,gas | Resolved by the user | ||

| Max. power of electric heating | 9 | 36 | 63 | 81 | 99 | |

| Outline dimension | 1.8x0.93x2.2 | 3x2.7x4.26 | 3.7x3.2x5.1 | 4.6x4.2x6 | 5.5x4.5x7 | Determined according to specific circumstances |

| Dry powder recovery | >95 | >95 | >95 | >95 | >95 | >95 |

- -What is the raw material? Material related characteristic? Does it corrosive, strong basicity, or highly acid? Please confirm.

- -What is the capacity per hour you need (kg/h)?

- -What is the initial moisture and final moisture of finished products you require to get?

- -What about the maximum heat temperature of raw material?

- -What kind of fuel you use to heat the dryer? Natural gas, electricity, fuel oil or steam?

- -Which equipment material do you like prefer? SUS304, SUS316L or Carbon steel?

- -Provide us your country’s electricity information, such as phases, voltage, HZ?

- -How about dust collect requirements?

Use Contrast

![]()

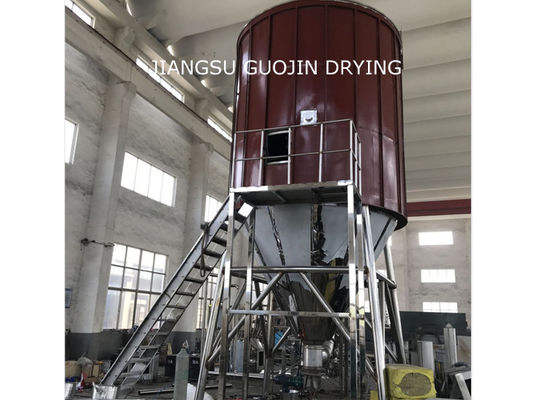

Product Show

![]()