CCSD Closed Cycle Spray Dryer For Special N2 Drying

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | CE |

| Model Number: | CCSD |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | CCSD Series Closed Cycle Spray Dryer For Special N2(Nitrogen) Drying | Model Type: | Pressure Spray Dryer |

|---|---|---|---|

| Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing | Place Of Origin: | Jiangsu, China |

| Power: | Depand On The Model | Certification: | ISO9001,CE |

| Key Selling Points: | Long Service Life | Warranty: | 1 Year |

| Material: | Stainless Steel , Carbon Steel | Control: | PLC Touch Screen |

| Heating Source: | Electricity/LPG/Natural Gas/Oil/Steam | ||

| Highlight: | Special N2 Drying Spray Dryer,Spray Dryer ISO9001,Closed Cycle Pressure Spray Dryer |

||

Product Description

CCSD Series Closed Cycle Spray Dryer for Special N2(Nitrogen) Drying

Closed cycled centrifugal spray drier is applicable for the solution, emulsified suspension and slurry which contains organic solvent, volatile toxic gas, or the material products are easy oxidation, and the solvent need to be recovered. It has not only all the advantages of the centrifugal spray drier, but also there is no powder discharged into the ambient air during the drying processing. The collection rate of the dry product is almost 100%. The solvent recovered by the recovery system can be used again and keep circulating in the system, so that production cost is reduced. It is widely applied in pharmaceutical and chemical industries.

Working Principle

First of all, filling the heated nitrogen into the tower, the liquid materials to be dried are transported to the

centrifugal atomizer by the liquid transport pump, then they are rotated in a high speed, and finally become the fine droplets, the droplets in the drying tower fully heat exchange with hot nitrogen, the liquid parts have been instant evaporated, the solid parts become powder materials down to the bottom of the drying tower, and then the dried powder will be discharged from the bottom of the tower.

Under the effects of the fan, the evaporated organic solvent passes through the cyclone separator, bag filter to remove the powder in the nitrogen, and then is condensed in the condenser. To avoid any liquid solvent to be brought out, we included a gas-liquid separator after the condenser.

The inert gas (such as nitrogen etc) works as drying media will be heated again and circulate in the system to form a closed cycle. XLP Closed Cyclone Spray Dryer works under the fully sealed system, the drying media is inert gas (such as nitrogen etc), and the working system is under positive pressure. The pressure transmitter will control the nitrogen inlet system to feed nitrogen when the system is under negative pressure, so to ensure pressure balance of the system.

It has a protective effect on the dry material since using nitrogen as the circulation carrier. The circulation

carrier, such as nitrogen will carry moisture, dehumidify and circulate in the system. The circulation carrier will be reused.

The conventional ordinary centrifugal spray drying has a continuous air supply, and air exhaust to reach the purpose of drying and the drying tower controlled under negative operation pressure, which is obviously different with the explosion-proof closed cycle spray drying system. So the explosion-proof closed circulation spray drying system is particularly suitable for drying the materials with organic solvents, toxic gas and the drying process need to protect the material from oxidation.

Features

| 1 | The design is explosion-proof, equipped with explosion release discs or vents on the main machine and the key part, so ensure the safety of the operation. (There's no explosion release discs or vents with volatile toxic gas, but the design is special) |

| 2 | The solvent will be recovered, so the product cost is low. |

| 3 | Adopt full closed design, so that the collecting rate of the finished product is very high, almost100%, which the other types of dryers are normally lower. |

| 4 | Equipped with washing tower device in the system, and adopt advanced atomizing rinsing device in order to improve the operational reliability. |

| 5 | For the oxidable material, the closed cycle spray drier use inert gas as the medium to ensure the materials will not be oxidized. |

Application

Food Industry:fatty milk powder,protein,cocona milk powder,substitute milk powder,egg white(yolk),food and plant,oats,chicken juice,coffee,instant dissoluble tea,seasoning meat,protein,soybean,peanut protein,hydrolysate and so forth.Sugar,corn syrup,corn starch,glucose,pectin,malt suagr,sorbic acid potassium and etc.

Medicine:Traditional Chinese medicine extract,ointment,yeast,vitamin,antibiotic,amylase,lipase and etc.

Plastics and resin:AB,ABS emulsion,uric acid resin,phenolic aldehyde resin,urea-formaldehyde resin,formaldenhyde resin,polythene,poly-chlor-oprene and etc.

Detergent:Common washing powder,advanced washing powder,soap powder,soda ash,emulsifier,brightening agent,orthophosphoric acid and etc.

Chemical Industry:Sodium fluoride(potassium),alkaline dyestuff and pigment,dyestuff intermediate,compound fertilizer,formic silicic acid,catalyst,sulphuric acid agent,amino acid,white carbon and so on.

Ceramic:aluminium oxide,ceramic tile material,magnesium oxide,talcum and so on.

Other:Calmogastrin,hime chloride,stearic acid agent and the cooling spray.

In order to quota you the right rotary atomizer spray dryer price / rotary atomizer spray dryer / lab rotary atomizer type spray dryer price, we would like to get the following information include in your inquiry:

- -What is the raw material? Material related characteristic? Does it corrosive, strong basicity, or highly acid? Please confirm.

- -What is the capacity per hour you need (kg/h)?

- -What is the initial moisture and final moisture of finished products you require to get?

- -What about the maximum heat temperature of raw material?

- -What kind of fuel you use to heat the dryer? Natural gas, electricity, fuel oil or steam?

- -Which equipment material do you like prefer? SUS304, SUS316L or Carbon steel?

- -Provide us your country’s electricity information, such as phases, voltage, HZ?

- -How about dust collect requirements?

- -Other special requirements?

Flow Diagram

![]()

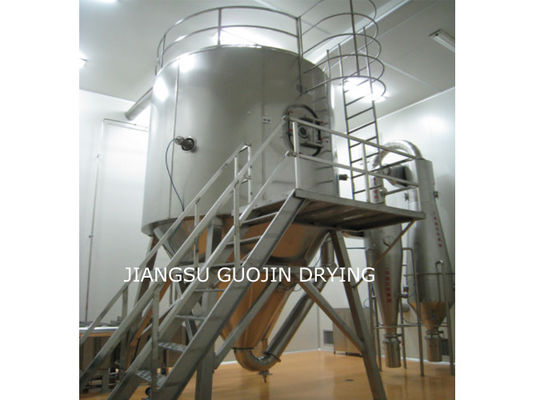

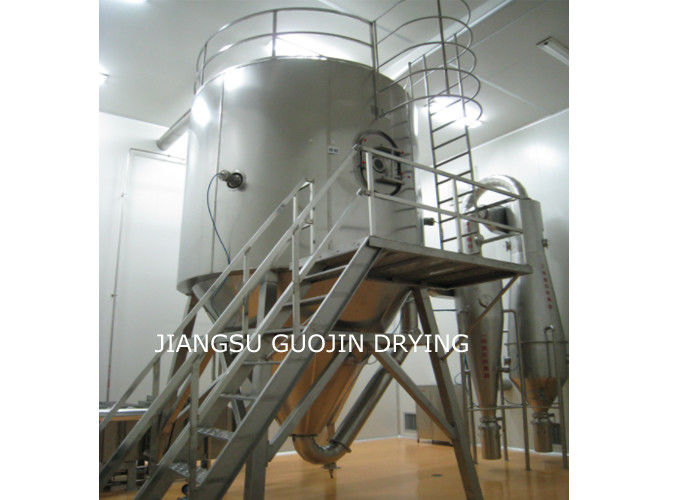

Product show

![]()