0.35KW Azo Dyes Pressure Nozzle Spray Dryer 25kg/h

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | CE |

| Model Number: | PNSD-25 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Item Name: | Tall Form Pressure Nozzle Spray Dryer For Azo Dyes | Model Type: | PNSD-25 |

|---|---|---|---|

| Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing | Water Evaporation: | 25 Kg/h |

| Diaphragm Pump Power: | 0.35 Kw | Diaphragm Pump Pressure: | It Can Be Regulated From 0.6-5, In General, It Will Be From 1 To 3. |

| Heating Way: | Electricity | Diameter Of Tower Body: | 1300 Mm |

| Total Height: | 7800 Mm | Control: | PLC Touch Screen |

| Highlight: | Azo Dyes Pressure Nozzle Spray Dryer,0.35KW Pressure Nozzle Spray Dryer,Pressure Spray Dryer 25kg/h |

||

Product Description

Tall Form Pressure Nozzle Spray Dryer For Azo Dyes

PNSD pressure spray dryer is suitable for solution, suspension, slurry, paste material, etc. Liquid material is atomized to small fog drops. And fog drops contact with hot air directly in the drying tower. Moisture content is evaporated instantly. So spray dryer features high efficiency, high mass transfer area, and short drying time, in general it is 5~30 seconds. Operating temperature can be adjusted according to actual situation, in general inlet air temperature is 150~500°C. And its automation control degree is control, environment solution environment can be solved.

Working Principle

The liquid or paste raw material is sprayed into small liquid drop by pressed sprayer draw assistance from pressure of diaphram pump, and quickly drying through amply heat exchange (10-90sec.).Most of the powder granules are collected from outlet of discharge at the bottom of the dryer. The wasted air and fine powder are separated by the cyclone, the wasted air is exhaust from draft fan, and fine powder is collected at the bottom of cyclone. There is a second grade duster equipped at the outlet; therefore, the recovery rate of the finished powder granule can be 96% to 98%.

Features

1. The machine has high efficiency to collect dust

2. Without the phenomenon of adhering wall

3. Energy saving and high efficiency

4. Particularly it is suitable for thermal sensitive material

5. Short drying time

Application

Foodstuff industry: Amino acid and similar substance, flavoring, protein, starch, dairy products, instant coffee, fish powder, meat powder, tomato paste and so on.

Pharmaceutical Industry: Chinese patent medicine, agrochemical, antibiotics, medical drinking agent and so on.

Chemical industry: Organic catalyst, resin, synthetic washing powder, thiamin, dyestuff, intermediate of dyestuff, intermediate of dyestuff, white carbon black, graphite, ammonium phosphate and so on.

Ceramic industry: Magnesium oxide, kaolin, metallic oxide, dolomite and so on.

Technical Parameter

| Model | PNSD-25 | PNSD-50 | PNSD-100 | PNSD-150 | PNSD-200 | PNSD-300 | PNSD-500 | PNSD-1000-2000 | |

| Water Evaporation capacity | 25 | 50 | 100 | 150 | 200 | 300 | 500 | The index can be affirmed in accordance with practical conditions. | |

| Diaphragm pump | Power(KW) | 0.35 | 4 | 7.5 | 11 | 15 | 22 | 30 | |

| Pressure(Mpa) | It can be regulated from 0.6 to 5, in general, it will be from 1 to 3. | ||||||||

| Heating way | electricity | electricity+steam | electricity+coal fuel oil hot air furnace | ||||||

| Diameter of tower body(mm) | 1300 | 1800 | 2400 | 2600 | 2800 | 3200 | 3800 | ||

| Total height(mm) | 7800 | 9200 | 11600 | 14000 | 15300 | 17100 | 19000 | ||

| Remark |

1. The evaporated amount is related to characteristics of raw material. The evaporated amount listed in the table is related to temperature. The data can be used for reference only. 2. The atomizing pressure and Model of pump will be equipped in accordance with the amount of raw material to be treated and the size require of product. 3. The power of fan should be iincreased suitably after equipped with cloth bag duster. |

||||||||

- -What is the raw material? Material related characteristic? Does it corrosive, strong basicity, or highly acid? Please confirm.

- -What is the capacity per hour you need (kg/h)?

- -What is the initial moisture and final moisture of finished products you require to get?

- -What about the maximum heat temperature of raw material?

- -What kind of fuel you use to heat the dryer? Natural gas, electricity, fuel oil or steam?

- -Which equipment material do you like prefer? SUS304, SUS316L or Carbon steel?

- -Provide us your country’s electricity information, such as phases, voltage, HZ?

- -How about dust collect requirements?

- -Other special requirements?

Flow Diagram

![]()

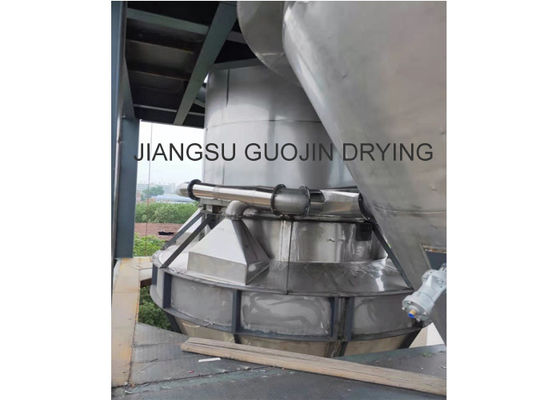

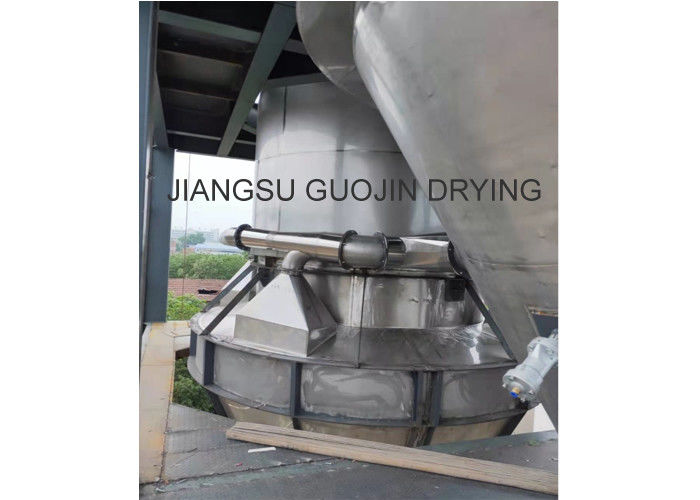

Product Show