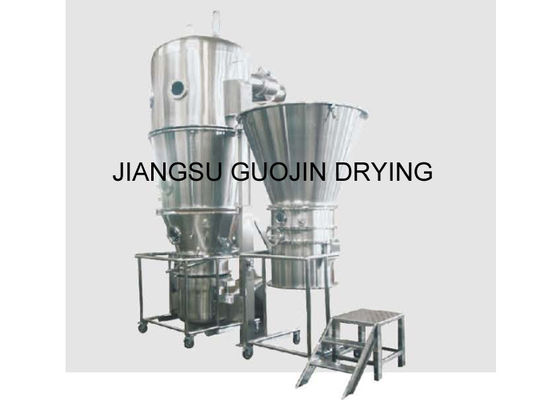

Stainless Steel Fluid Bed Coater With ABB Motor

Product Details:

| Place of Origin: | China |

| Brand Name: | Guojin |

| Certification: | ISO |

| Model Number: | FBC |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Item Name: | Stainless Steel Fluid Bed Coater With ABB Motor | Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing |

|---|---|---|---|

| Condition: | New | Place Of Origin: | Jiangsu, China |

| Power: | Depand On The Model | Certification: | ISO9001 |

| Key Selling Points: | Long Service Life | Warranty: | 1 Year |

| Material: | Stainless Steel | Drying Type: | Batch Drying |

| Heating Source: | Electrical, Steam | Motor Brand: | ABB/Siemens |

| Highlight: | Stainless Steel Fluid Bed Coater,ABB Motor Fluid Bed Coater |

||

Product Description

Stainless Steel Fluid Bed Coater With ABB Motor

Fluidized bed coating machine is a new type of particle coating equipment that organically combines fluidization coating technology and spray technology. it is widely used for film slow controlled release, skeleton slow controlled release pill coating, particle and powder coating.

Product Application

- Phamaceutical industry: tablet, capsule, low sugar or no sugar granule of chinese medicine.

- Fodstuff: cocoa, coffee, milkpowder, juice of granulate, flavoring and so on.

- Other industries: peticide, feed chemical fertilizer, pigment, dyestuff and so on.

- Drying of powder or granule wet material.

- Coating: granule, pill protection layer, color preparedness, sustained release, film, enteric coating.

Technical Advantage

1. Bottom spray fluidization, the material has a certain regular running track, so uniform and continous coating can be obtained.

2. Coating powders, granules and pills to mask taste, prevent moisture, oxidation, water, heat, color and isolation etc.

3. No coating material loss and low production cost.

4. The route for the fog particles to reach the materials is short and there is no "spray drying" problem.

5. Cylindrical acceleration container or inverted cone deceleration design can be used to coat particles, large particles, small particles and pellets.

6. The material dispersity is excellet and there is no adhesion phenomenon.

Technical Parameters

Product Show

electrical, steam, natural gas or other