1000kg Freeze Drying Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM |

| Certification: | CE;ISO |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard export Carton |

| Delivery Time: | 20-30days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Type: | Vacuum Drying Equipment | Drying Capacity (kg): | 1000 Kg |

|---|---|---|---|

| Application: | Medicine Processing, Chemicals Processing, Food Processing, Fruit | Condition: | New |

| Voltage: | 380v | Power(W): | 50v |

| Key Selling Points: | Convenient Operation. Energy Saving. Remote Control | Warranty: | 1 YEAR |

| After-sales Service Provided: | Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training | Weight (KG): | 20t |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts | Applicable Industries: | Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops |

| Local Service Location: | None | Showroom Location: | None |

| Function: | Multifunctional | Product Name: | Freeze Dryer |

| Raw Material: | Fruit And Vegstable And High Value | Capacity: | 10-2000kg Per Batch |

| Highlight: | 1000kg Freeze Drying Machine,Vacuum Freeze Drying Machine,1000kg/batch Freeze Drying Machine |

||

Product Description

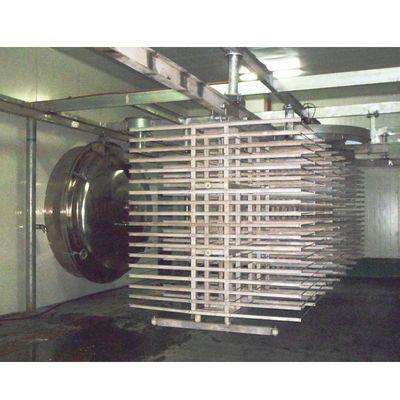

1000kg Freeze Drying Machine

Product Description

Summary

The vacuum freezing and drying technology is currently the most advanced dehydrating processing technology in the world. Compared with the commonly used drying method, the freezedried food produced by lyophilizer features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste and high content of nutritious components the dried food basically remains unchanged in its volume and shape,looks like sponge and has no shrinking.

Brief introduction

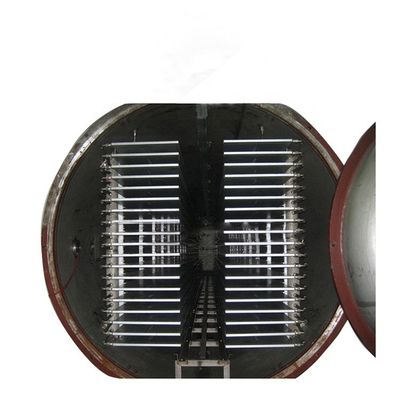

lyophilizers are consisted of food pre-freezing system, freezing and drying pot, heating system, vacuum system,

refrigerating system, material conveying system and control system, etc.

The vacuum system adopts the combination of water-sealed pump and oil-sealed pump. The way of heating is closed water circulation heating. And the condenser is placed inside heating tank besides the heating plates. Of course, it can be customized according to the practical condition, for example, placed above the drying pot.

refrigerating system, material conveying system and control system, etc.

The vacuum system adopts the combination of water-sealed pump and oil-sealed pump. The way of heating is closed water circulation heating. And the condenser is placed inside heating tank besides the heating plates. Of course, it can be customized according to the practical condition, for example, placed above the drying pot.

Working principle

After some pretreatments, in a low temperature and vacuum surroundings, the inner moisture of the foodstuff will sublimate from

solid state to gaseous state so that the foodstuff is dried.

The whole processing line including the following parts

1. pretreatment system

2. freezing and drying tank

3. heating system

4. vacuum system

5. refrigeration system

6. material conveyor

7. control system

solid state to gaseous state so that the foodstuff is dried.

The whole processing line including the following parts

1. pretreatment system

2. freezing and drying tank

3. heating system

4. vacuum system

5. refrigeration system

6. material conveyor

7. control system

| Model | FD-2 | FD-5 | FD-10 | FD-20 | FD-50 | FD-100 | |||

| drying area | 2.4m2 | 5.0m2 | 10m2 | 20m2 | 50m2 | 100m2 | |||

| load capacity | 24kg/batch | 50kg/batch | 100kg/batch | 240kg/batch | 500kg/batch | 1000kg/batch | |||

| tray size | 540x460x30 mm | 635x545x35mm | 870x545x 35 mm | 700x460x30mm | 635x545x35mm | 635x545x35mm | |||

| tray number | 8pcs x2 | 16pcs x2 | 22pcs x2 | 60pcs x2 | 144pcs x2 | 288pcs x2 | |||

| drying pot size | φ700x2000mm | φ1200x2280mm | φ1600x 2900 mm | φ1800x 2600 mm | φ2400x 5200mm | φ2400x 9100 mm | |||

| operation vacuum | 13.3~200 pa | ||||||||

| heating plate temp | normal temperature~+120℃ | ||||||||

| electric method | 6kw | 15KW | 24KW | 36KW | 96KW | -- | |||

| steam capacity | -- | -- | -- | -- | 150kg/h | 260kg/h | |||

| 0.7 mpa | 0.7 mpa | ||||||||

| cold load | 11.1KW | 18KW | 110KW | 180KW | |||||

| dimension | 4.3x2.2x1.8m | 7.4x2.3x2.4m | designed by client plant | designed by client plant | |||||

| power | 20KW | 31kw | 57kw | 104.5KW | 130kw+ | 249kw | |||

Application

The vacuum freezing and drying machine can be widely used in various fields, such as vegetables, fruits, condiments, seafood,biological products, medicine, beverage, specimen, etc.

Want to Know more details about this product